All your questions about sterilization optimization, explained simply.

Stainless steel sterilization equipment

Designed to meet the needs of the products and autoclave manufacturers.

Sturdy and efficient sterilization equipment.

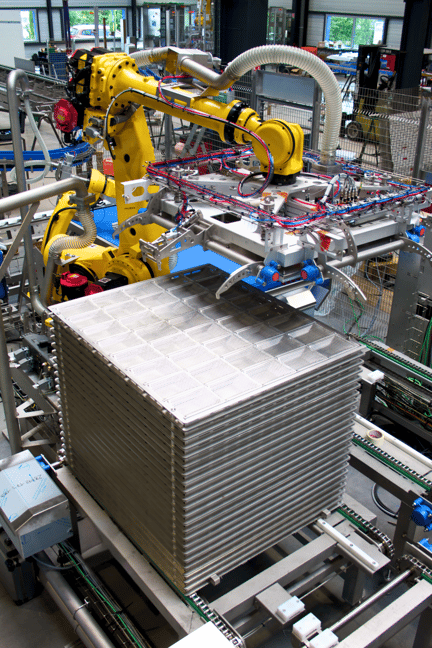

The equipment is designed to adapt to the needs of the food, medical and other industries. They are compatible with all types of autoclaves and enable automation of production lines.

Thanks to its expertise, TSA offers innovative solutions such as stainless steel containers and baskets to reduce sterilization costs. This optimizes energy consumption, productivity and the quality of sterilization processes. The products, designed for all types of autoclaves, meet hygiene standards and are optimized for ergonomics and lightweight design.

Explore the different sterilization equipment

We distribute 3 categories of equipment to ensure complete sterilization of your products.

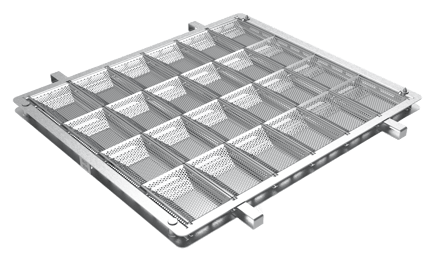

Sterilization trays and baskets

For secure holding of packaging without risk of marking with a special design for pouches and doypacks.

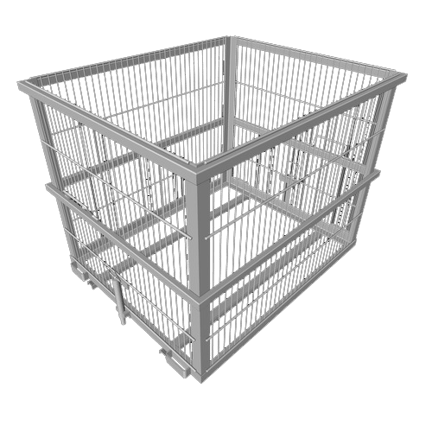

Sterilization containers

For sterilization of cans and glass jars, allowing efficient fluid circulation.

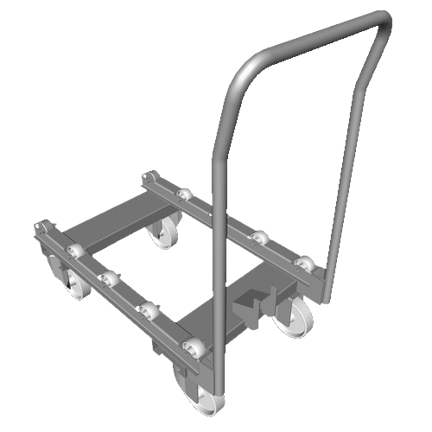

Trolleys and base frames

A transport and handling solution adapted to your sterilization equipment for smooth integration into your processes.

How does TSA equipment optimize sterilization?

How do TSA stainless steel containers and baskets improve the efficiency of autoclaves in sterilization processes?

TSA stainless steel containers and baskets are designed to promote optimal fluid circulation and even heat distribution, improving autoclave efficiency and reducing processing time.

How do TSA's energy consumption innovations impact the profitability of sterilization operations?

TSA's innovations, such as patented solutions to reduce thermal inertia, help minimize energy consumption while maintaining high sterilization performance, thereby increasing operational profitability.

What ergonomic and safety benefits do TSA products offer for handling workers sterilization equipment?

TSA products are designed to be lightweight and ergonomic, making them easier to handle while reducing the risk of musculoskeletal disorders (MSDs) among personnel. In addition, their robust design ensures user safety.

How does TSA ensure that its products meet hygiene and safety standards in the baby food, pet food, and medical sectors?

TSA ensures its products are manufactured with high-quality, corrosion-resistant, and easy-to-clean stainless steel materials, ensuring they meet the strict hygiene and safety standards specific to each sector.

How does TSA adapt its products to the different types of autoclaves used in sterilization processes?

TSA products are designed to be compatible with all types of autoclaves (static, rotary, oscillating), thus offering maximum flexibility to adapt to different equipment and specific user needs.

Your everyday challenges

When you share your goals and challenges with us, we respond by analyzing your needs and proposing high-performance, tailored solutions.