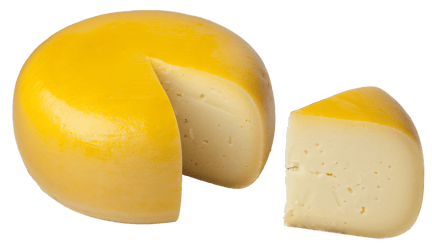

Give cheese a perfect finish

Cheese coating machines ensure a smooth and even finish while saving time and energy.

Cheese coating machines for your cheeses

Coatings are designed to control cheese aging and protect them. They are applied in several stages and require several layers.

Coating machines apply consistent layers, minimizes coating consumption and increases productivity.

Coating step-by-step

Coating happens in 3 key steps:

Protection after brining

After brining, the first layer will protect the cheese during its first days of ripening. A bioprotector can be added to the coating at this time. To ensure good adhesion, the cheese surface must be dried in a drying room or with a Tecnical drying tunnel.

Aging

Coating layers are applied through out the aging of the cheese. The coatings control the aging of the cheese. The coating layers reduce exchanges with ambient air, controlling water loss and develops flavor.

Packaging

The final layer often has a marketing function, coloring the surface of the cheese or adding a muslin label.

Options

Options based on your needs:

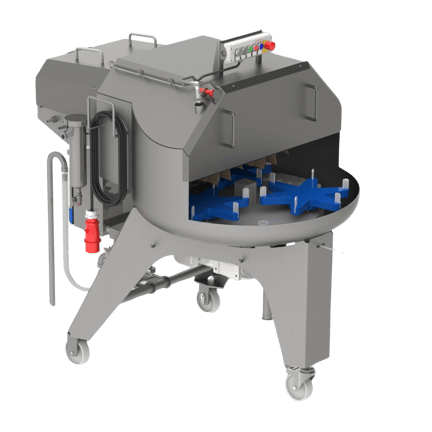

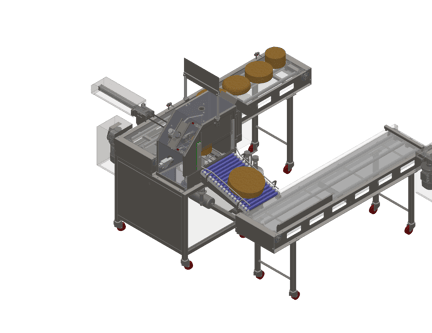

Automatisation

Semi-automatic on wheels or automatic in-line to adapting to wheel volume.

.png?width=432&height=289&name=image%20(6).png)

Application

By flaps transfer or pulverization

Cheese

Machines adapted to the shape of cheeses.

Advantages

Features of the coating machines:

Loss reduction

Reduction of coating consumption.

Quality

Application of a consistent layer over the entire cheese

Efficiency

Efficiently saving time coating cheese and cleaning.

We also distribute cheese coatings!

Your everyday challenges

When you share your goals and challenges with us, we respond by analyzing your needs and proposing high-performance, tailored solutions.